Forklifts are indispensable equipment in today’s industrial facilities and warehouses. In a warehouse, for example, forklifts are used to store and retrieve goods such as food, beverages, paper, and pharmaceuticals. Forklifts are classified into different categories depending on how they are powered and their lifting capacity, which can range from a couple of boxes to multiple goods containers. Now, imagine a scenario where two hundred forklifts are deployed in an industrial warehouse complex operating round-the-clock to keep up with the demand for goods. Without a system in place to monitor the operation of these forklifts, the warehouse will quickly descend into chaos and become a safety hazard for both people and machines. In this article, we highlight the success story of a forklift manufacturer in Italy who recently upgraded the surveillance systems on its forklifts to provide real-time on-site monitoring capabilities to customers, thereby ensuring safe and efficient operation of the forklifts to increasing productivity in warehouse operations.

Keeping an Eye on the Operation

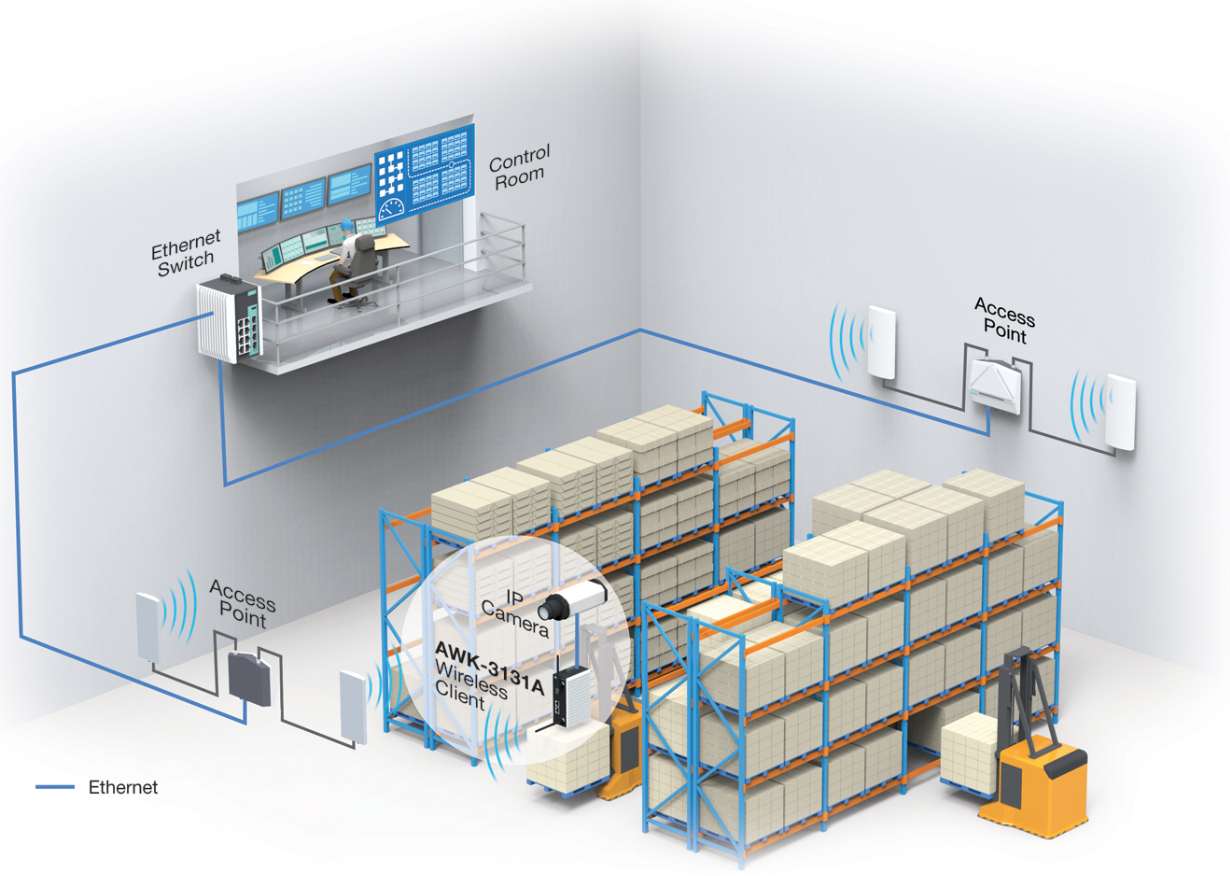

An operator in the control room of a warehouse needs to be able to continuously monitor the movement and operation of the forklifts deployed throughout the facility to ensure the efficient storage and timely movement of goods to their destinations, while adhering to the most stringent safety standards to avoid accidents. The best way to achieve this is to mount surveillance cameras on the forklifts to live stream videos of the operations to the control center. Operators in the warehouse control center can thus get a complete picture of the on-site operations of the forklifts and can take action to coordinate the activities, improve safety, and increase productivity of the forklift systems.

The Wireless Advantage

The forklift manufacturer was looking for a Wi-Fi solution that can provide easy-to-deploy devices for installation on forklifts. The devices must also seamlessly connect with existing 3rd party APs in the system. The network should provide enough Wi-Fi bandwidth to support live streaming of video data from IP cameras installed on the forklifts.

How It All Came Together—The Success Story

Over 200 forklifts installed with surveillance cameras need a reliable wireless network to ensure live streaming of video to the control center. To achieve this, each IP camera onboard the forklifts is connected to an AWK-3131A wireless client, which transmits real-time video data to the control center.

Moxa’s AWK-3131A supports the client-router mode, which eliminates the need for an extra switch, thereby simplifying the installation of devices. The AWK-3131A can operate with third-party APs, making it easy to deploy them in existing wireless networks and to connect them to the SCADA system in the control center.

The AWK-3131A supports the 802.11n standard to provide data rates up to 300 Mbps, which is ideal for live video streaming over a wireless network. Turbo Roaming technology in the devices enables millisecond-level handoff time for AWK-3131A wireless clients, ensuring constant wireless connectivity so that the forklifts can perform their tasks more efficiently.

Moxa’s AWK-3131A industrial IEEE 802.11a/b/g/n wireless AP/client provides the following benefits to ensure a reliable wireless network for efficient forklift operations in warehouses:

- Client-router mode in devices to simplify network deployment

- Interoperability with existing 3rd party APs

- Data rates up to 300 Mbps for video-streaming applications

- 150 ms client-side handoff with Turbo Roaming technology

To learn more, download our portfolio of AMH success cases.