It is no secret that converting industrial protocols often comes down to burning the midnight oil, and engineers’ frustrations with this time-consuming task are duly noted. Hence, it’s no surprise that they are always on the lookout for ways to sidestep these tedious steps. Now, there is good news: A user-friendly standalone gateway that guides engineers within 60 seconds through the whole configuration process makes protocol conversions much easier.

Since the advent of the Industrial Internet of Things (IIoT), protocol conversion has been the key to connecting legacy and multivendor devices to networks. The most common protocol conversion is Modbus-RTU-to-Modbus-TCP conversion, and is usually required when metering devices, mostly using Modbus RTU, need to be integrated with SCADA systems, mostly using Modbus TCP. For factory or plant owners, this kind of integration ensures that they reap the benefits of the IIoT, such as reducing energy consumption while maximizing productivity.

Protocol conversion is normally done in one of three ways. The first option is to write a program on an embedded computer or industrial PC. The cost may be relatively low from a hardware point of view, but it requires a software engineer who knows C language extensively. The second option is to use a small PLC that supports software add-on protocol library or a hardware communication module. It requires PLC programmability and additional expenditure. Both options require that engineers must be familiar with protocols’ behavior so that they are able to handle exceptions.

The third option is to use a Modbus protocol gateway. It is a standalone protocol converter that is easy to use and integrate, and it comes with dedicated functions, for example, troubleshooting. Deploying Modbus protocol gateways helps quick integration for a large number of Modbus RTU devices. Thus, for inexperienced engineers, there is no need to worry that they would be stumped by an insufficient knowledge of protocol.

The MGate MB3000 Series, which includes the MGate Manager tool, addresses engineers’ pain points to make the integration of protocol gateways easy. The tool supports a user-friendly graphical interface and a clear step-by-step design to guide users through the whole configuration process in a very short time.

We will take a closer how MGate Manager helps you complete configuration within 60 seconds.

Step 1: Find Your Modbus Gateway

MGate Manager (see figure below) helps you search for and configure the gateway. You could also use the gateway’s web console. First, click the Search icon so that the MGate Manager can find your gateway. It will show up as in the example below.

.png?width=500&height=322)

Next, click the Configuration icon and enter the password for your gateway. This will take you to the configuration page for your gateway.

.png?width=500&height=342)

Step 2: Select Slave or Master Mode

A page for the mode selection for the gateway will open. You can use the diagrams to determine which mode fits your scenario, depending whether you want your gateway take on a master or slave device role.

.png?width=500&height=466)

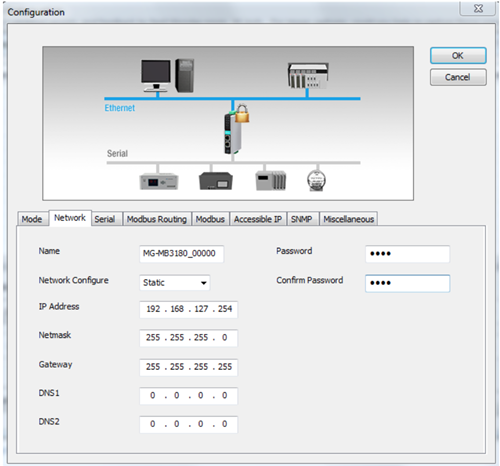

Step 3: Assign an IP Address

Click on the Network tab to assign an IP address and netmask for the gateway. If you’re still using the default password for the gateway, you can change its password as shown in the figure below.

Step 4: Set Serial Parameters

In the Serial tab, you can adjust the serial parameters to match settings needed by your Modbus slave device. Then, click OK, and the configuration is done.

Conclusion

MGate Manager will help engineers save many hours of arduous configuration. In a nutshell, it is configuration with instant results. What’s more, the configuration can also be done via the product’s web console. To read more about this new intuitive tool that's even smaller than your business card, visit the MGate Series MB3180 product pages.